Stanlow oil refinery owner EET unveils plan to build 125MW hydrogen-fuelled power plant by 2027 that will help decarbonise its operations and provide power for the wider power grid. Tony McDonough reports

EET aims to have a hydrogen power plant operational at Stanlow by 2027

EET Fuels says it will have its hydrogen-fuelled power plant at Stanlow up and running by 2027, supplying power for its own operations and for the wider power grid.

In April LBN revealed how EET (part of the Indian-owned Essar Group), was aiming to transform Stanlow, located at Ellesmere Port close to the River Mersey, into the world’s first decarbonised oil refinery.

Stanlow is the second-biggest oil refinery in the UK and supplies 16% of the country’s road fuels as well as providing jet fuel for multiple airports, including Liverpool and Manchester.

It will also be the main hub for the North West-wide HyNet hydrogen project which will supply hydrogen to factories across the region. Costing tens of billions of pounds HyNet will see a £3bn hydrogen production and carbon capture plant built at Stanlow.

This will produce so-called blue hydrogen by burning natural gas. Instead of releasing carbon emissions that contribute to global warming, the CO2 will be captured and stored in depleted gas fields under Liverpool Bay.

HyNet is awaiting final Government backing, due to come in the autumn. However, this method of producing hydrogen is seen as controversial with some experts calling into question the viability of carbon capture and storage on this scale.

Employing around 750 people directly, with double that number on site when you include contractors, Stanlow produces about 2m tonnes a year of CO2 which makes it the biggest emitter in the region.

Furnaces are essential to an oil refinery. The process of refining crude oil means it has to be heated to around 470 degrees celsius. Stanlow’s ‘catcracker’ furnace alone accounts for almost half of the refinery’s annual emissions.

EET has invested £45m in a new furnace which is now installed on the site. Although it can operate using conventional fuels it is also equipped to operate using hydrogen and will do so once HyNet is up and running.

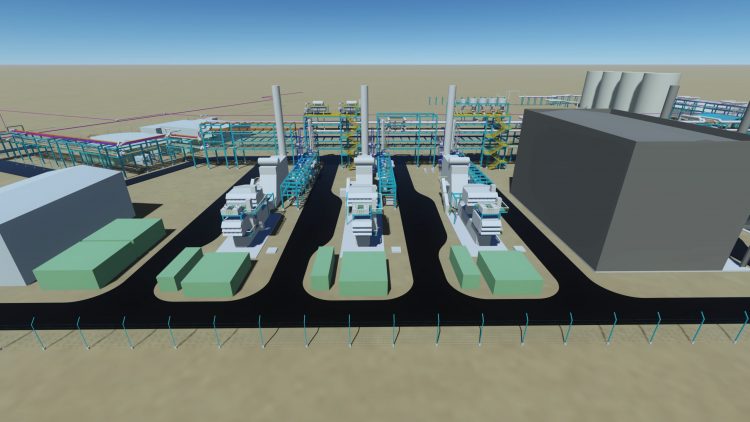

Operational by 2027, EET Hydrogen Power will purchase hydrogen from the hydrogen production plants and supply power and steam to the refinery. It expects to produce more power than the refinery needs so excess power will be exported to the grid.

EET Hydrogen Power will be developed over two phases to reach a capacity of 125 MW of power with 6,000 tonnes per day of steam, with the hydrogen replacing hydrocarbons delivering a reduction of 740,000 tonnes of carbon dioxide per year.

The new plant will replace Stanlow’s existing boiler units, which currently generate approximately 50MW of power for the refinery operations.

Rob Wallace, chief executive of EET Hydrogen Power, said: “We have bold ambitions for Stanlow to become a low carbon transition hub at the centre of the HyNet Industrial cluster.

“EET Hydrogen Power will be Europe’s first 100% hydrogen-ready gas-turbine plant which will be supplied with EET Hydrogen’s low carbon hydrogen. This project will create significant benefits by contributing to regional emissions’ reductions targets.”

READ MORE: Liverpool still behind the pace for foreign investment

EET includes EET Hydrogen Power, EET Fuels (owner of the Stanlow refinery), EET Hydrogen, (which is developing blue and green hydrogen capacity) and Stanlow Terminals.

Tony Fountain, managing partner of Essar Energy Transition, added: “Launching EET Hydrogen Power shows the progress that Essar Energy Transition is making in delivering against its commitment to put the UK at the forefront of low carbon energy.

“EET Hydrogen Power helps bring this commitment to life and demonstrates our intention to globally showcase the pathway to decarbonising vital high emitting industries.”

The post Stanlow hydrogen power plant to switch on in 2027 appeared first on Liverpool Business News.